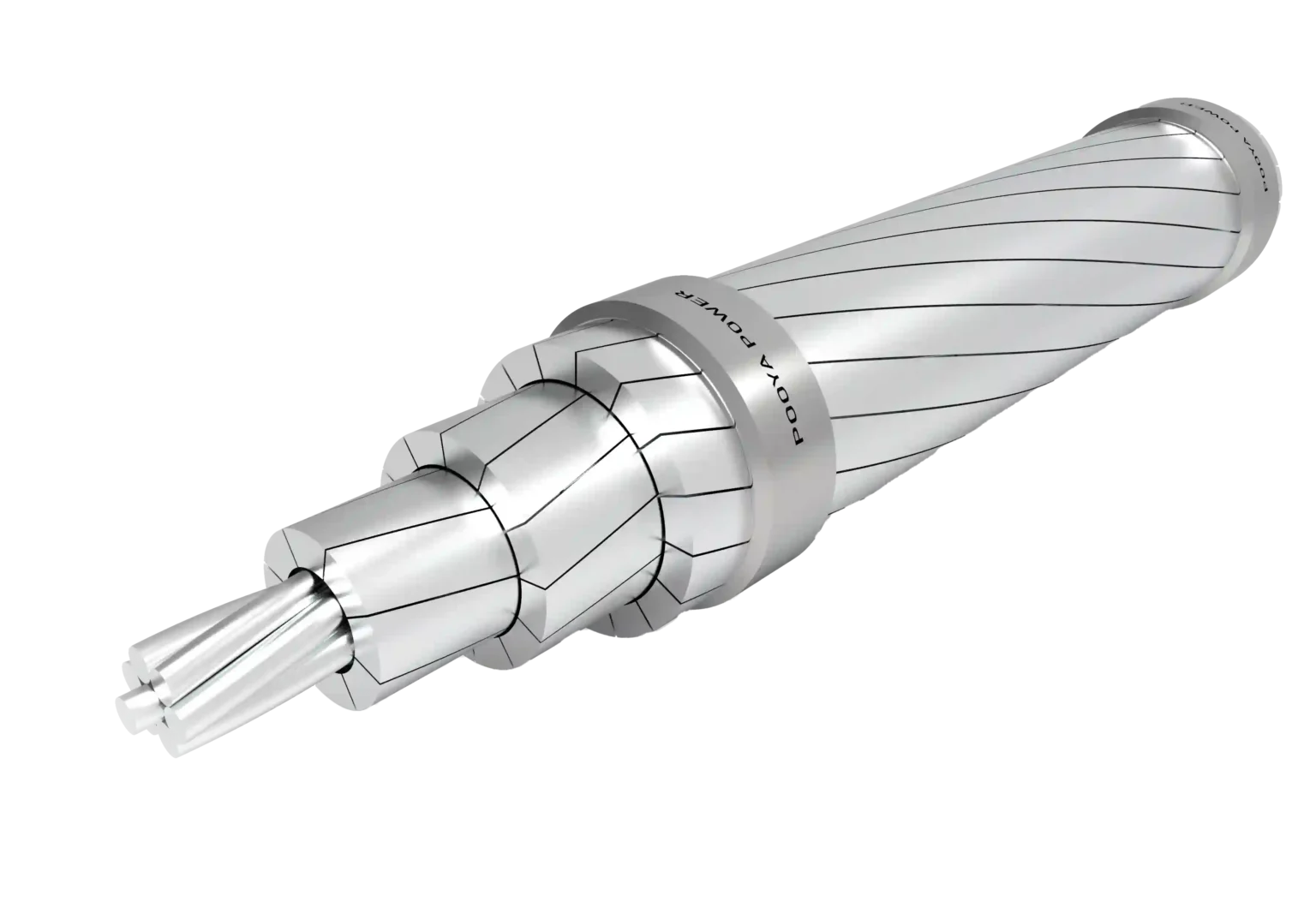

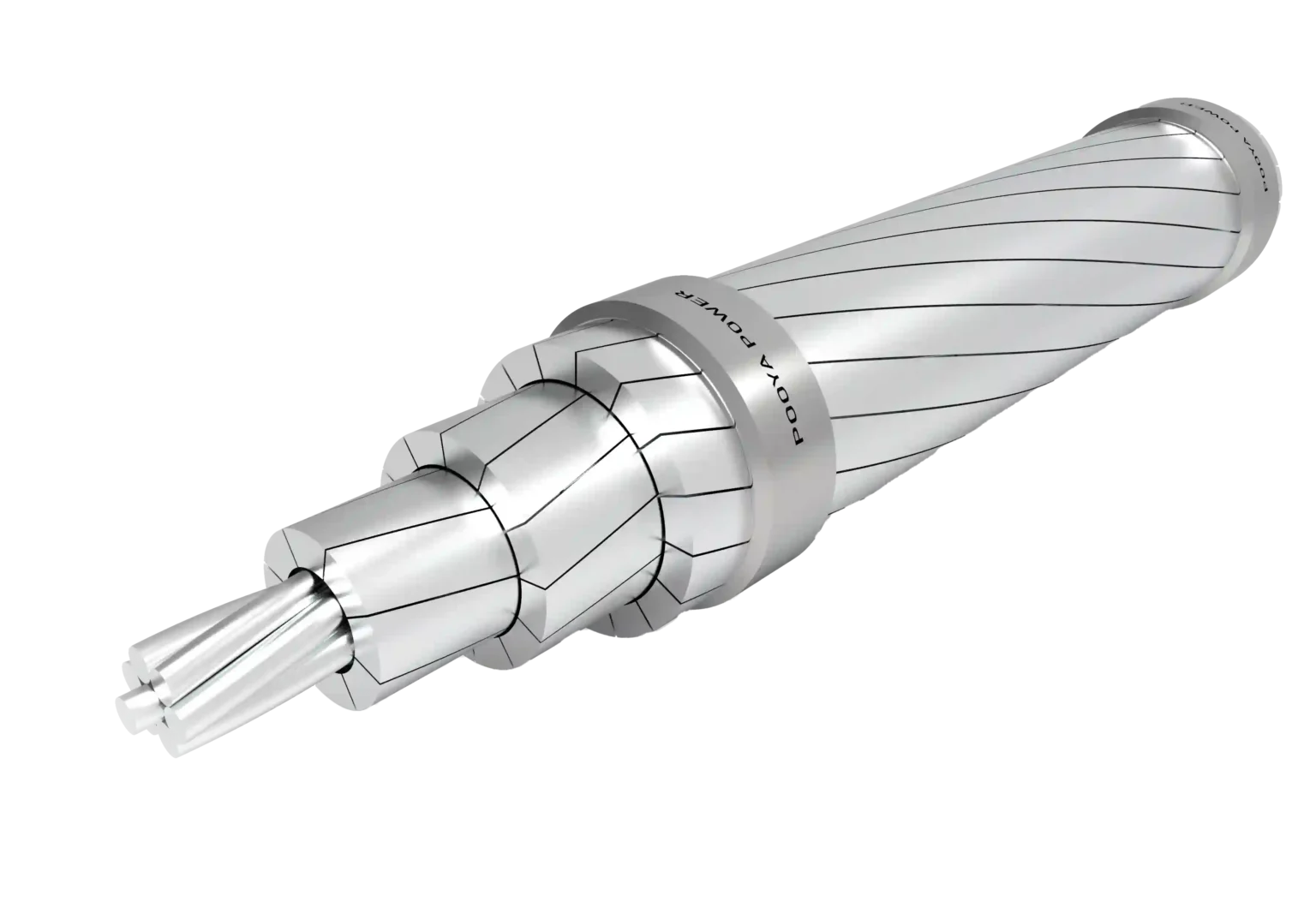

All Aluminium Conductor (AAC/TW) conductors, produced by Pooya Power Knowledge Enterprise, are composed of trapezoidal 1350-H aluminum wires, ensuring enhanced current transmission and reduced energy loss.

Technical Specifications:

Please select a standard and then a conductor from the lists above to display its specifications.

In the realm of overhead conductors, efficiency and reliability are crucial. All Aluminium Conductor (AAC/TW), produced by Pooya Power Knowledge Enterprise, are composed of trapezoidal 1350-H aluminum wires, ensuring enhanced current transmission and reduced energy loss. Their compact design and reduced diameter further optimize performance, while also minimizing the impact of aerodynamic forces on the conductor. These conductors offer versatility and suitability for low, medium, and high voltage lines, as well as short and medium spans.

All Aluminium Conductor (AAC/TW), also known as all-aluminum conductors with trapezoidal wires, stand out for their aluminum composition, unlike traditional ACSR conductors that include a steel core. The trapezoidal wire design contributes to their efficiency, enabling improved electricity transmission with reduced loss (approximately 10% to 15%).

The combination of fully aluminum strands alongside their trapezoidal cross-sections and compact design results in lower electrical resistance compared to ACSR conductors and even their counterparts, AAC/RW conductors with round strands. These factors contribute to reduced mass per unit length of the conductor, decreased line losses (between 10 to 15 percent), minimized aerodynamic forces impacting the conductor, and improved self-damping performance of AAC/TW conductors. While aluminum has lower mechanical strength than steel, AAC/TW conductors are well-suited for shorter and medium spans. Moreover, they exhibit exceptional corrosion resistance, forming a protective oxide layer that enhances longevity, especially in coastal and humid environments.

All Aluminium Conductor (AAC/TW) feature a more compact design and the use of trapezoidal-shaped strands provides a larger contact area between the aluminum strands. This results in increased mechanical stability and reduced vibrations caused by wind. This feature is particularly beneficial in windy areas with variable weather conditions, as it can extend the lifespan of transmission lines. Additionally, the trapezoidal shape of the strands improves stress distribution within the conductor, helping to prevent mechanical damage caused by repeated bending and thermal stresses. Due to the reduction of aerodynamic forces acting on the conductor, AAC/TW conductors can be highly effective in projects that require minimizing the impact of wind on transmission lines. Furthermore, with their all-aluminum structure and optimized cross-section, AAC/TW conductors are a cost-effective option for power transmission projects in areas with special environmental needs, such as protected or environmentally sensitive regions.

Another significant advantage of AAC/TW conductors is their high current-carrying capacity. Due to the trapezoidal cross-section of their strands and a more compact design, these conductors can accommodate higher current levels compared to those with circular cross-sections. This characteristic makes AAC/TW conductors suitable for applications in high-load networks and regions with harsh weather conditions. Additionally, their lighter weight and reduced susceptibility to wind and ice loads allow AAC/TW conductors to decrease the loading on transmission lines, thereby minimizing construction and maintenance costs. Furthermore, the uniform and homogeneous structure of these conductors enhances their resistance to corrosion and abrasion, extending their service life.

AAC/TW conductors advantages:

- Enhanced current transmission and reduced energy loss

- Compact design and reduced diameter

- Lower impact of aerodynamic forces on the conductor

- High electrical conductivity and minimal electrical resistance

- Superior corrosion resistance