The Aluminium Conductor Steel Supported (ACSS) represents a category of High-Temperature-Low-Sag (HTLS) conductors, offering distinct advantages over conventional ACSR conductors. ACSS conductors feature the incorporation of 1350-O annealed aluminium wires in contrast to the standard 1350-H19 variant used in ACSR conductors. This substitution results in noteworthy enhancements. Notably, annealed aluminium wires boast a higher electrical conductivity of 63% IACS, compared to the 61.2% IACS conductivity of drawn, hardened aluminium wires utilized in ACSR conductors. Consequently, ACSS conductors are capable of carrying increased electrical current.

ACSS/GA

The ACSS/GA conductor is a kind of High-Temperature Low-Sag conductors. The most important difference between ACSS conductors compared to ACSR conductors is the use of 1350-O annealed aluminum wires instead of hard-drawn 1350-H aluminum wires which enhances the current-carrying capacity and operating temperature of these conductors.

ACSS/MA

ACSS/MA conductors are made of round aluminium wires stranded around a steel core. The steel core in ACSS/MA consists of Galfan-Coated steel wires. Galfan is composed of Zinc - %5 Aluminium - Mischmetal which enhances the corrosion resistivity of the core. The use of Galfan-Coated steel wires improves the lifespan and operating temperature of ACSS/MA conductors.

ACSS/AW

ACSS/AW conductors, employing aluminium-clad steel wires in their core, boast higher electrical conductivity and improved corrosion resistance compared to ACSS/GA and ACSS/MA conductors. Compared to both ACSS/GA and ACSS/MA types, the ACSS/AW can operate at higher temperatures as the adhesion between the substrate and the coating is higher for aluminium-clad steel.

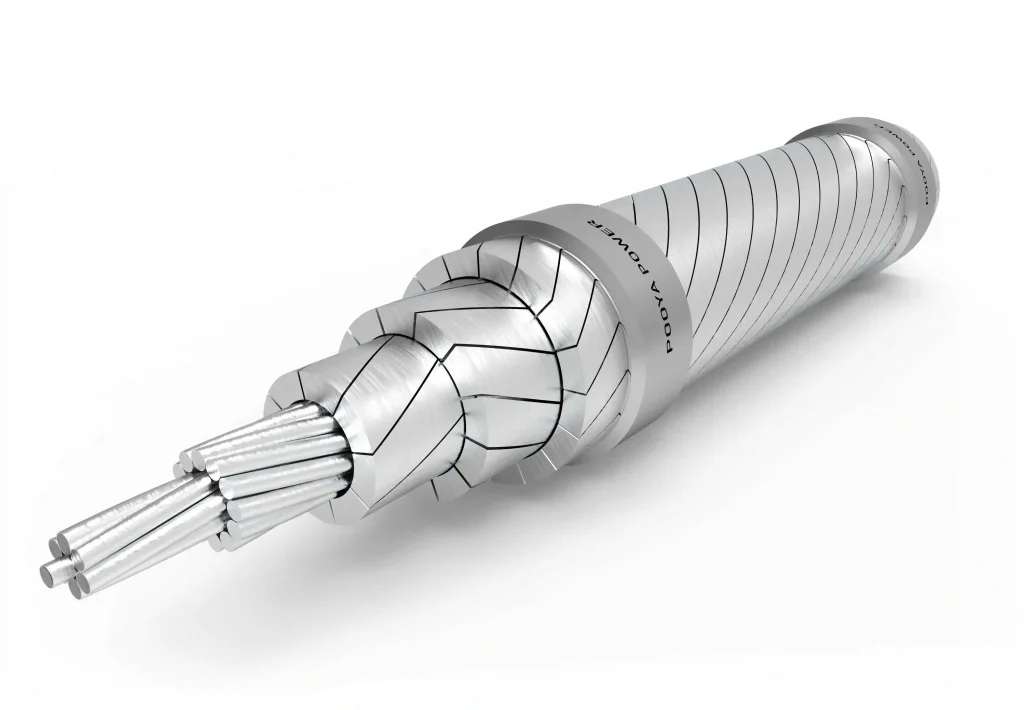

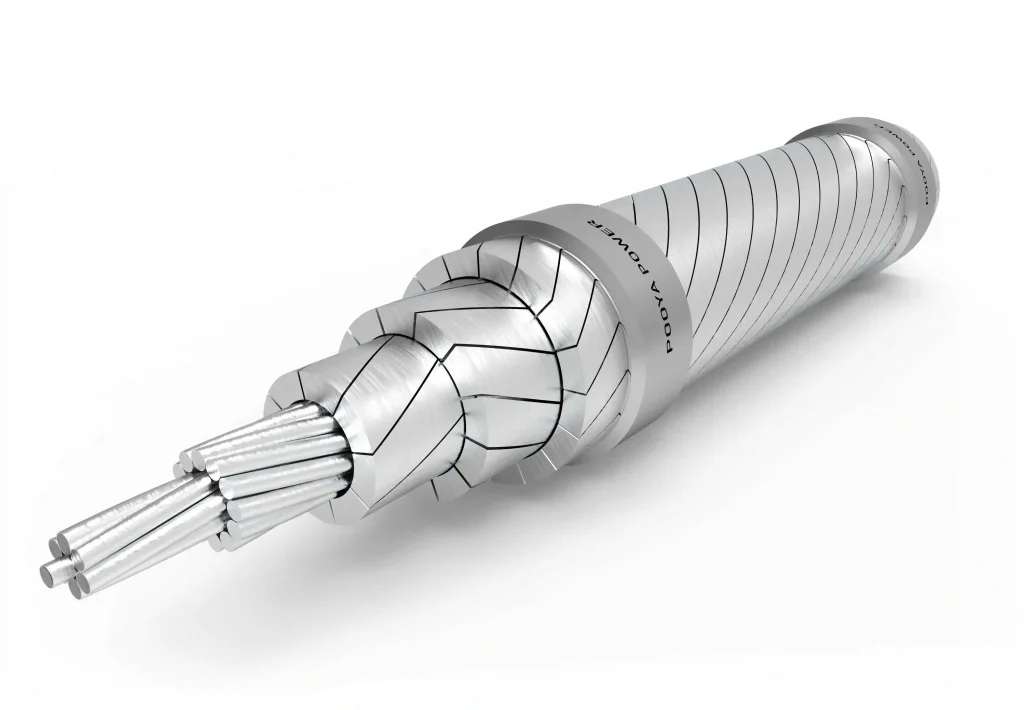

ACSS/TW

ACSS/TW conductors utilize trapezoidal aluminium wires instead of conventional round wires. While conventional ACSS conductors employ circular aluminium strands, the utilization of trapezoidal-shaped aluminium strands offers enhanced current transmission, reduced energy loss, compact design, and reduced diameter. Trapezoidal aluminium strands boast a larger cross-sectional area.

ACSS/AW-TW

ACSS/AW-TW conductors utilize trapezoidal aluminium wires wounded around a steel core made up of aluminium-clad steel wires. The combination of trapezoidal aluminium wires and aluminium-clad steel core enhances the electrical and anti-corrosion properties of this type of ACSS conductors compared to conventional ACSS conductors.