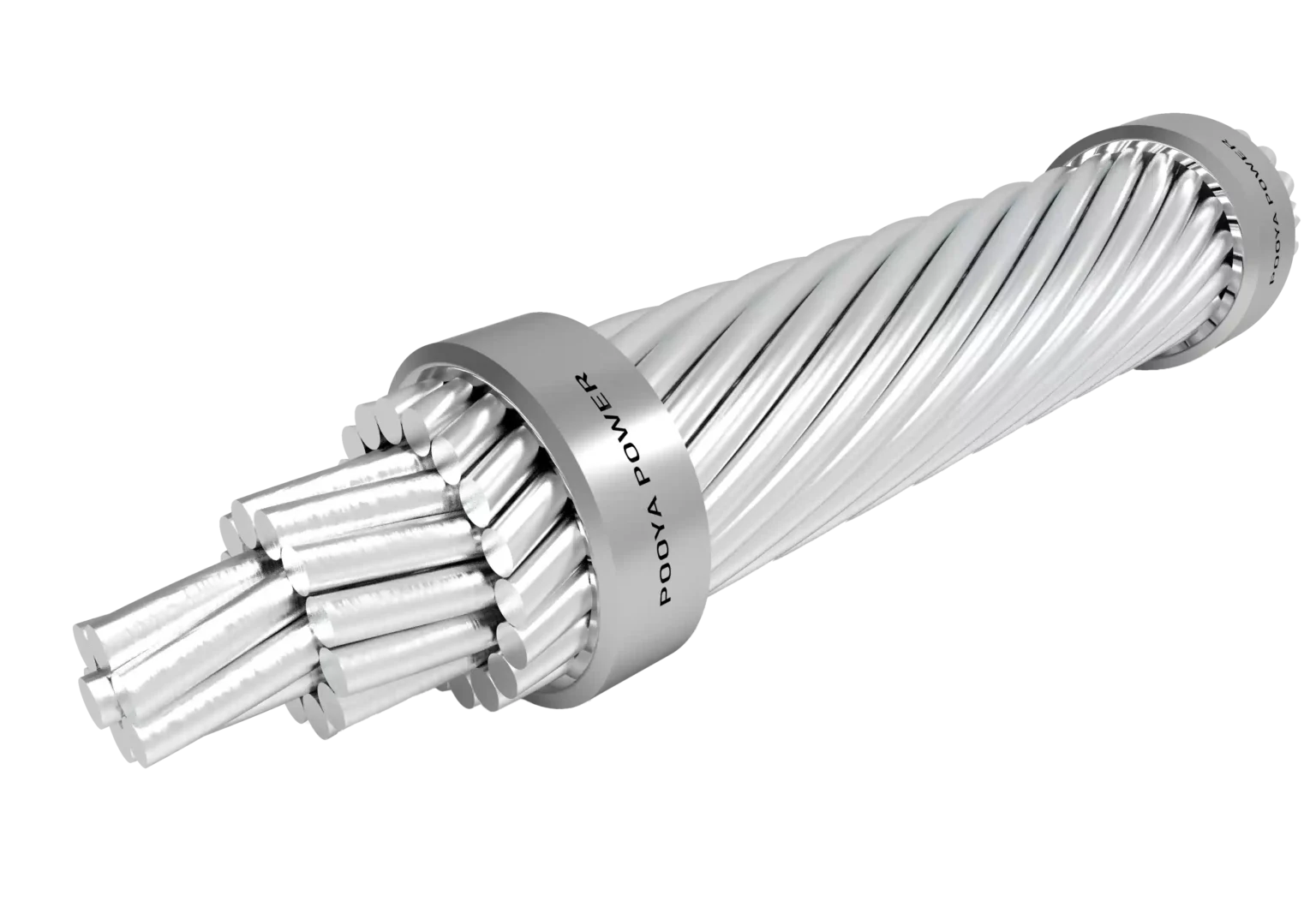

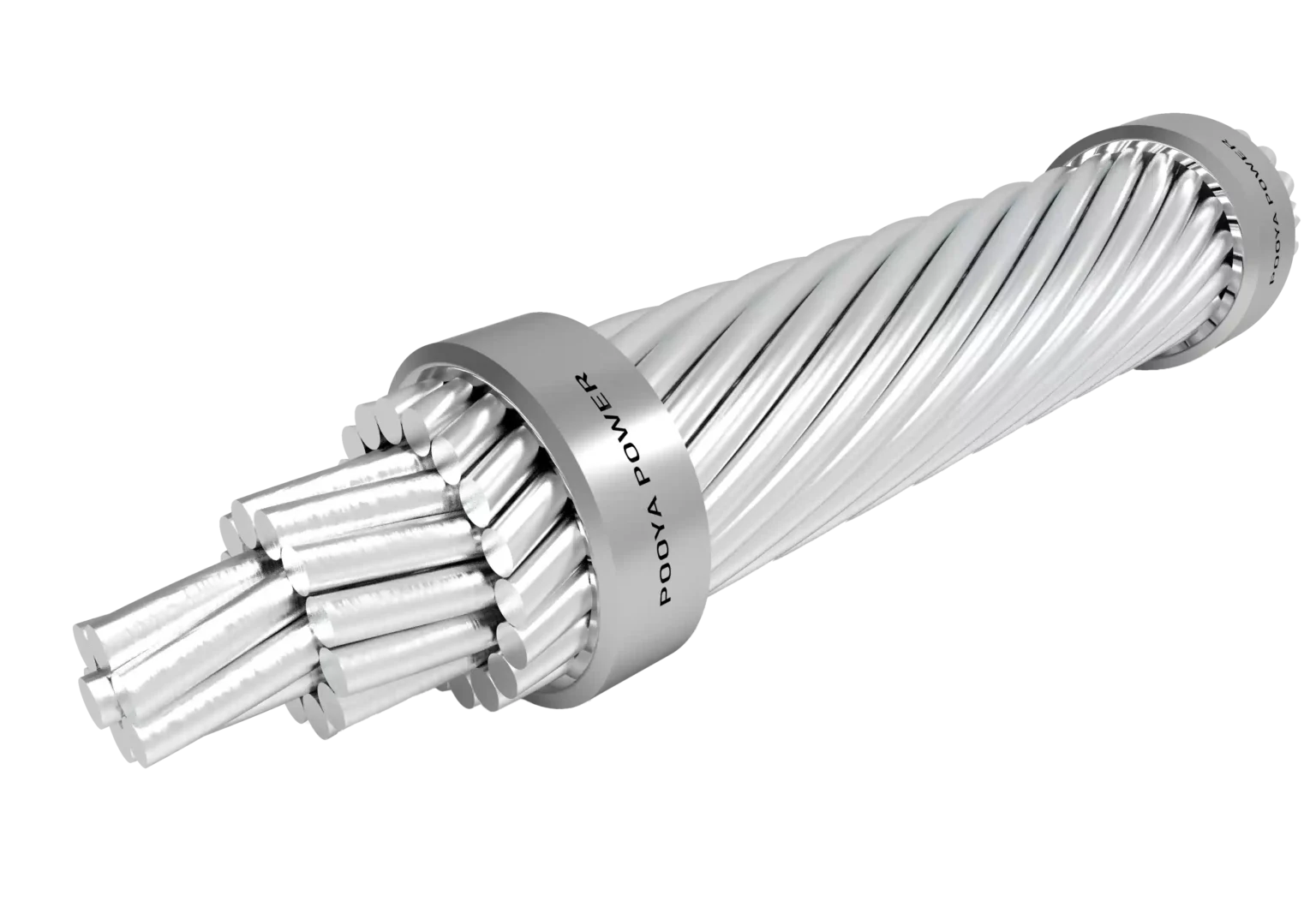

The Aluminium Conductor Alloy Reinforced (ACAR) conductor amalgamates 1350-H19 aluminium strands with 6201 or 6101 aluminium alloy wires enriched with aluminium-magnesium-silicon (Al-Mg-Si) elements. In the architecture of ACAR conductors, the 1350-H19 aluminium wires are skillfully stranded around a core comprising one or more aluminium alloy wires characterized by circular cross-sections. ACAR conductors are engineered to strike an exceptional equilibrium between mechanical robustness and electrical efficiency.

Technical Specifications:

Please select a standard and then a conductor from the lists above to display its specifications.

The Aluminium Conductor Alloy Reinforced (ACAR) conductor amalgamates 1350-H19 aluminium strands with 6201 or 6101 aluminium alloy wires enriched with aluminium-magnesium-silicon (Al-Mg-Si) elements. In the architecture of ACAR conductors, the 1350-H19 aluminium wires are skillfully stranded around a core comprising one or more aluminium alloy wires characterized by circular cross-sections. ACAR conductors are engineered to strike an exceptional equilibrium between mechanical robustness and electrical efficiency.

A distinguishing attribute of Aluminium Conductor Alloy Reinforced (ACAR) is their commendable blend of tensile strength and electrical properties. In comparison to AAC conductors, ACAR conductors exhibit heightened tensile strength. Although their tensile strength is surpassed by ACSR conductors, ACAR conductors outperform the latter in terms of electrical characteristics. This advantageous combination of mechanical and electrical attributes positions ACAR conductors as a compelling choice in various applications.

The adoption of ACAR conductors in lieu of ACSR conductors engenders a twofold benefit: reduced line loss and enhanced line construction efficiency. This strategic substitution enables the optimization of construction costs while simultaneously curbing line loss. By meticulously balancing these factors, the decision to deploy Aluminium Conductor Alloy Reinforced (ACAR) presents an opportunity for a judicious and cost-effective choice, aligning with the overarching objectives of line construction and performance optimization.

These conductors can be utilized in projects that require a balanced combination of mechanical strength and electrical conductivity. Therefore, Aluminium Conductor Alloy Reinforced (ACAR) is an excellent choice for use in areas facing a mix of mechanical challenges and the need for optimal electrical performance, such as mountainous regions, areas with high temperatures, or long-distance transmission lines that require reduced energy losses. Their design allows for enhanced durability while maintaining efficient energy transfer, making them suitable for a variety of demanding applications in the power transmission sector.

Another significant advantage of Aluminium Conductor Alloy Reinforced (ACAR) is their excellent corrosion resistance. The aluminum alloys used in the construction of these conductors naturally form a stable oxide layer on their surface, which protects them from corrosive agents. This characteristic makes ACAR conductors an ideal choice for use in coastal, industrial, and high-humidity environments.

ACAR conductors advantages:

- Greater strength-to-weight ratio relative to AAC conductors

- Favorable electrical characteristics

- Outstanding corrosion resistance